- Production Capacity

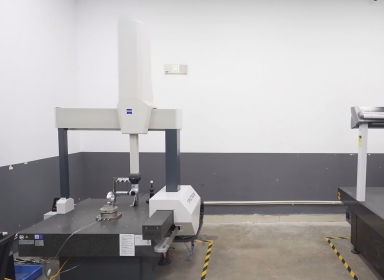

- Quality Assurance

With a complete quality inspection system, stable quality, low return rate, and a pass rate as high as 90%

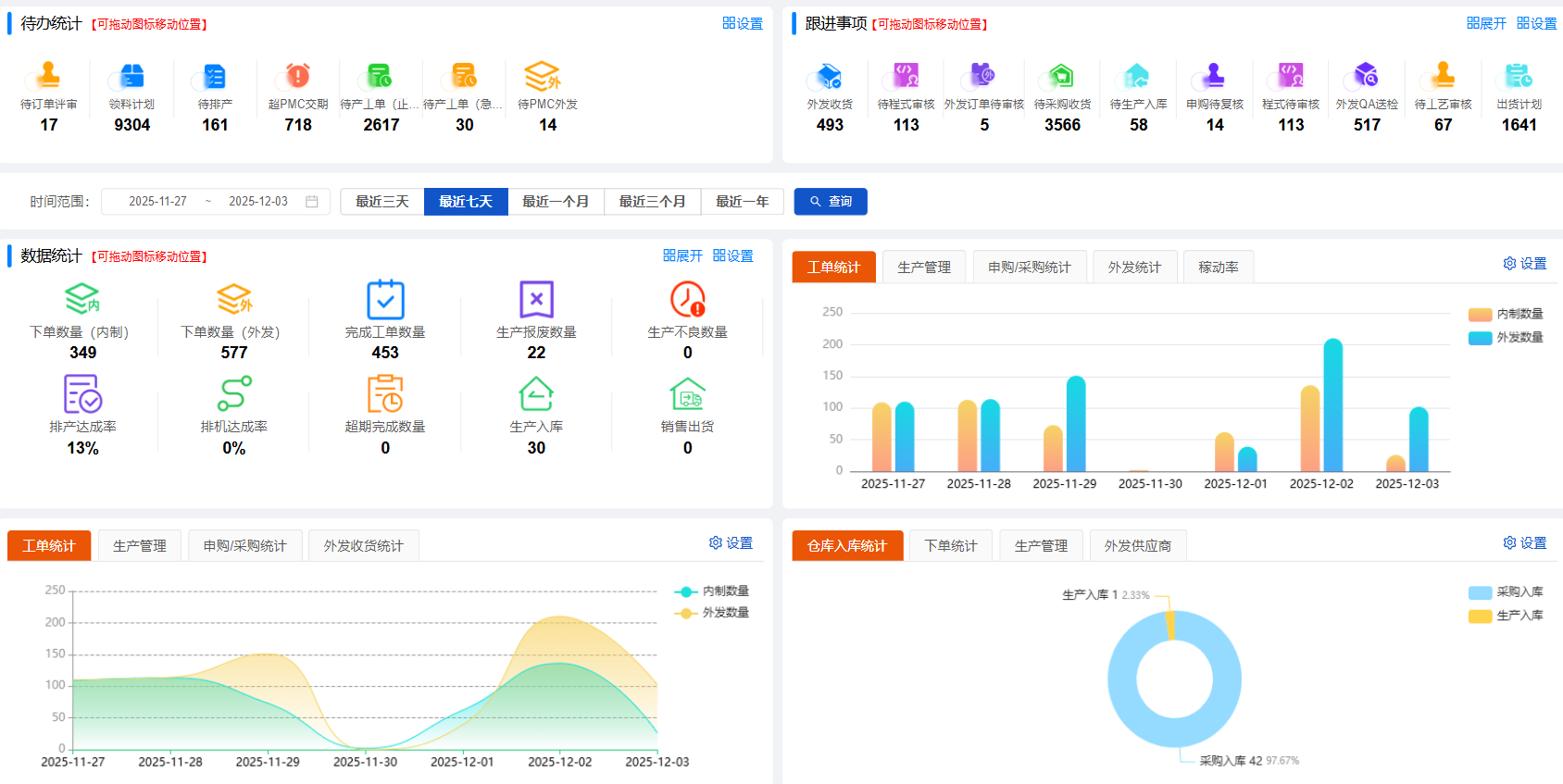

APX system offers fast quotes, fast order processing, and fast response

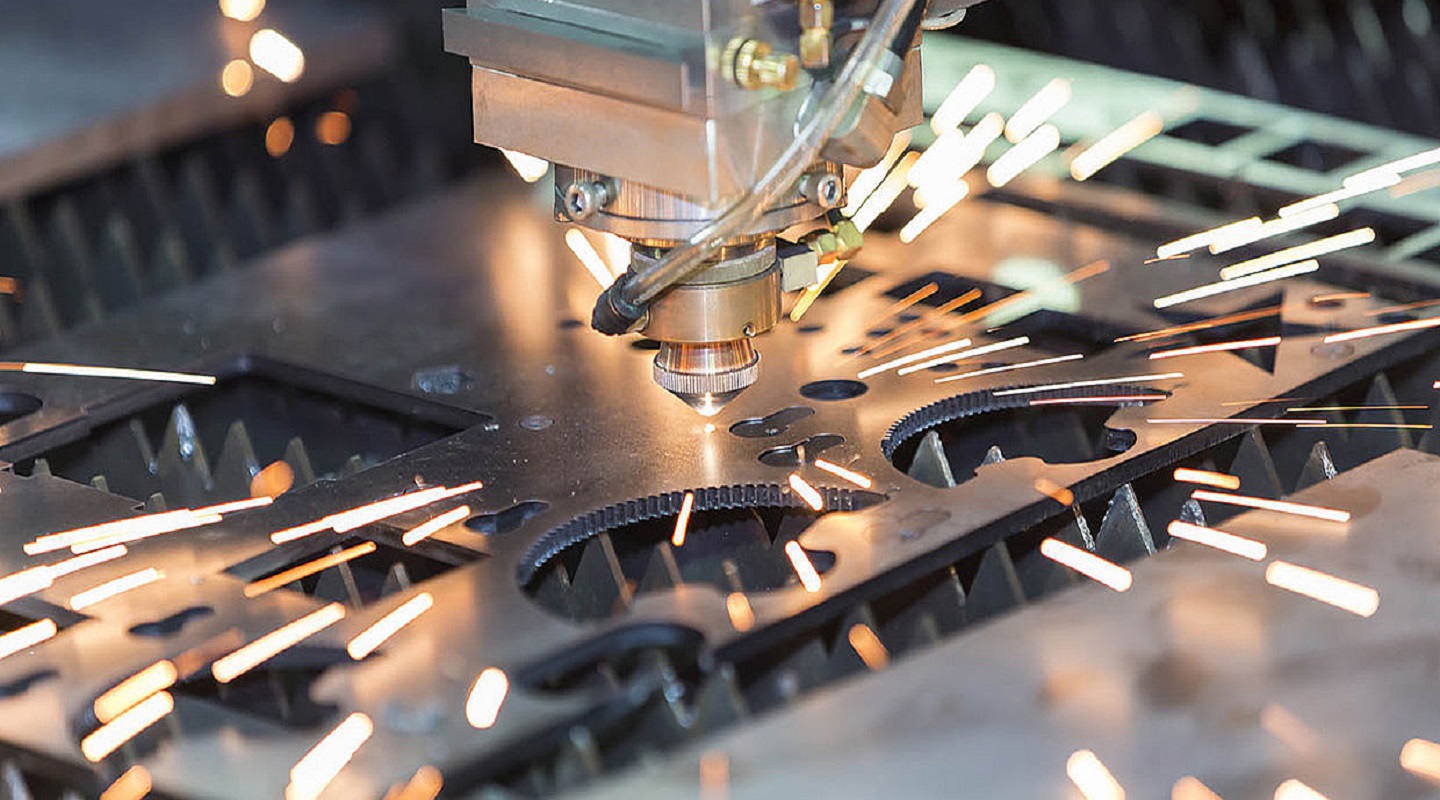

Specializing in machining complex, high-precision parts with deep cavities, blind holes, and multiple surface treatments, achieving an accuracy of ±0.005mm

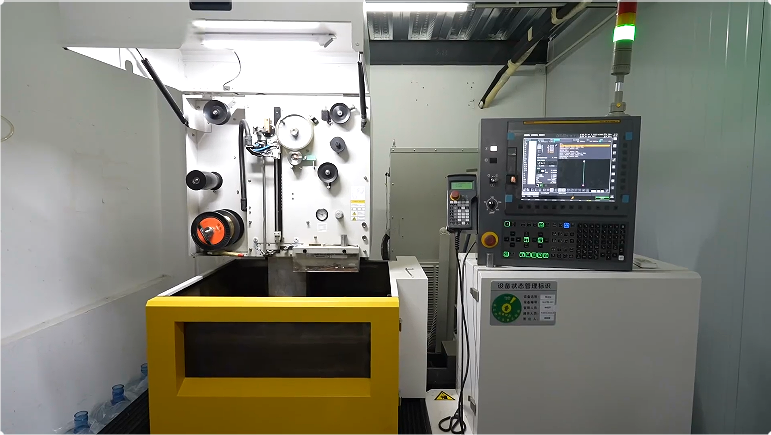

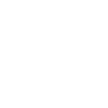

Lights-out factory, fully automated, operating 24/7

Customized modules, tailored for mass,high-mixed,low volume high-precision machining parts

Over 300 state-of-the-art 5-axis, 4-axis and 3-axis machining centers, including DMG, FANUC and TSUGAMI

Advanced technologies, engineering designs and customized design services. The technical engineering team has accumulated 20 years of experience

Widely applied in aerospace, medicine, semiconductors, automation, automobiles, new energy, and optoelectronic communication,etc

Overview of Fukuno

Specialized in precision mechanical parts

Over 300 CNC machines, machining tolerance up to 0.005mm

The plant covers over 30,000 square meters and has more than 500 employees.

Material capability: Aluminum, Bronze, Copper, Alloy Steel, Stainless Steel, Tool steels, Titanium, PEEK,POM,ABS.etc.

- 20,000㎡Facility

- 500+Employees

- 300+Advanced CNc Machine

- 3Manufacturing Plants

- 1200+Number of Customers

-

The Hannover MESSE in Germany was successfully concluded

-

Fukuno Precision Celebrates Success at Hannover Industrial Fair 2025

-

Exhibtion MANUFACTURING WORLD JAPAN 2023

-

Fukuno intelligent plant

-

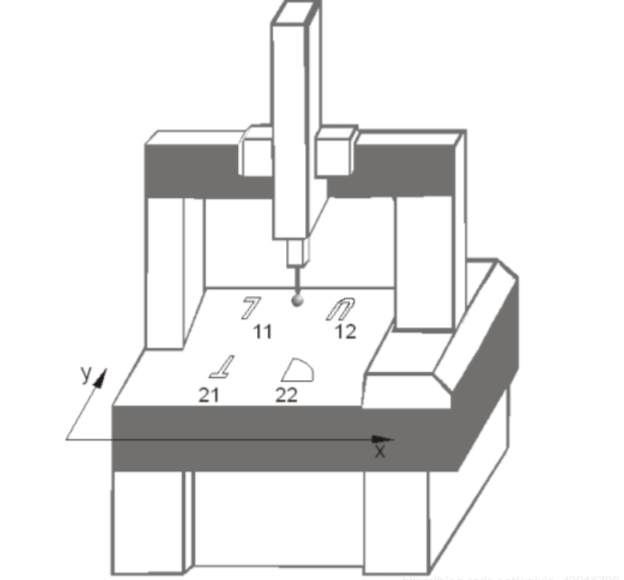

What the coordinate measuring device is?

-

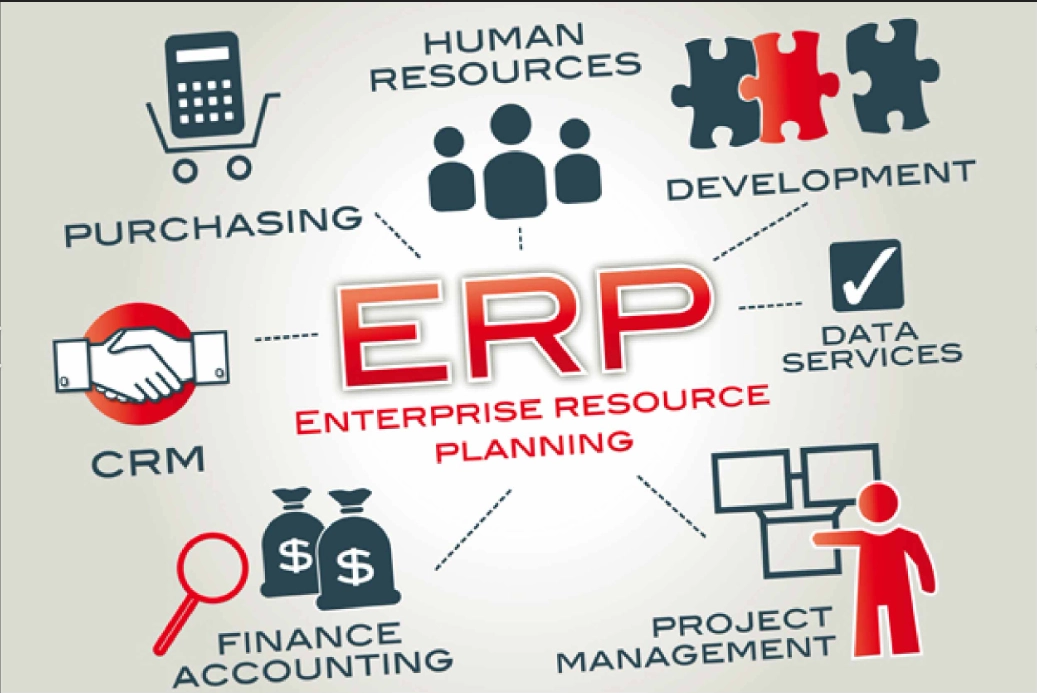

What isERP & QR system?